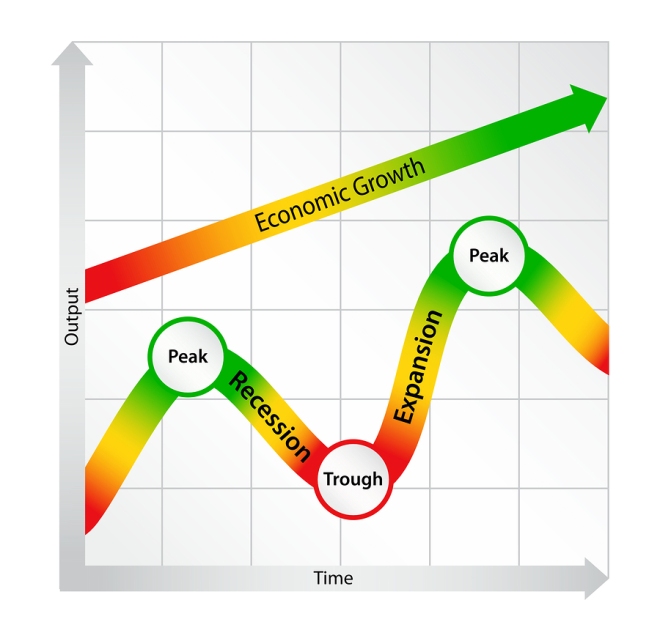

Most organizations face few peak demand periods and much longer off-peak periods. A peak is defined as a surge of demand that is above normal fluctuations. The throughput generated during the peaks is, many times, very substantial relative to the total throughput generated in a year. Thus, handling the peak has to be regarded as a key strategic issue, setting the relationships between the policies employed for the peak period and the different policies for off-peak periods. The operational criticality of the peak is that it is reasonable to expect the internal weakest link to become an active constraint during the peak, and be non-constraint during the off-peaks. This is often caused by the recognition that the level of available capacity maintained by the organization should broadly match the requirements during a peak.

If it is possible not only to prevent the loss of sales and the cost of holding too much inventory but also to strengthen the reputation of the organization then such a move, developing a TOC solution for peaks, has to be part of the overall strategy of the organization.

An important article entitled Peak Management, by Boaz Ronen, Alex Coman and Eli Schragenheim, was published back in 2001 in the International journal of Production Research. A post, publish in May 2016 in this blog, Facing Seasonality, the True Problematic Issue, offered some focused ideas on handling an anticipated peak that repeats itself every year. The link appears at the end of this post.

Generally speaking we need to discuss three related time periods when we design the most effective way to handle a peak:

- The off-peak period before the peak itself, where the appropriate planning and preparations, like producing or purchasing the appropriate stock levels for the peak, are taking place. One generic insight for planning for the peak is to draw some of the typical peak demand to the off-peak periods around the peak. This could be achieved by pricing in a way that encourages customers to buy before or after the peak. Certainly airlines, hotels, and the whole vacation business are well tuned to these means. Others should adopt the generic insight to their specific environment.

- The policies, priorities and processes during the peak itself, using most effectively the limited degrees-of-freedom. This definitely includes the actual exploitation of the active constraint, and the subordination. For instance, a policy to offer only part of the product-mix and services during the peak, while offering the whole choice at off-peaks should be seriously considered.

- The after-the-peak period has to deal with some ramifications of the peak, which need to be considered in the planning. It is usually not possible to go to “normal” behavior immediately after the peak. The policies that fit the peak are different than during the off-peak. Human resources usually need to rest after the pressure during the peak, causing a true slow period after the peak that is lower than the average off-peak activity. Inventories that were not purchased during the peak have to be taken care of. Many times such inventories are sold at significantly reduced price in order to reach the normal off-peak stable behavior. The overall success or failure to draw the most from the peak depends not only on what is sold during the peak, but also on what happens after the peak. For instance, the contribution from a promotion depends a lot on how deep is the drop in sales after the promotion.

First let’s distinguish between four different types of peaks defined by two parameters: very short peaks versus long peaks and anticipated peaks versus unanticipated. The post on seasonality is focused mainly on anticipated long peaks of demand. Let’s now deal with the other three types.

Short anticipated peaks

A “short” peak means that during the peak there is no valid way to replenish the stock during the peak. In services it could mean there is no way to add resources that have not been prepared before the peak for such a case. So, basically what you have at the start of the peak is the maximum you can hope to use.

Consider for instance a major sport event, like the Super Bowl, which generates two different types of short peaks. One is sales of special items connected with the specific event, like hats and shirts with the logo of one of the teams. There is no valid opportunity to replenish the initial inventory of hats during the peak. The other type is a service like the police that have to be ready for any possible disruption. It is not practical in such an event to be able to bring more security people in a hurry to handle a sudden problematic situation, unless they are held on alert very close to the stadium.

The ultimate dependency on early prediction of the requirements within the peak makes it the focus of the analysis. Hence, the quality of the forecast and the decision rules based on that forecast are the core of the preparations.

As already have appeared elsewhere in this blog, forecasts of one number lead to wrong answers. The only way to gain forecasting information that can be used for sensible decisions is to come up with two forecasts, one is based on reasonably pessimistic one and the other on an optimistic one.

The pessimistic forecast provides the vital information of what should definitely be prepared a-priori. The optimistic forecast should lead the decision by how much to add risk in the specific case. The possible damage of every quantitative decision, like preparing N items in stock, can be estimated by checking two scenarios. One assumes that the demand would be according to the pessimistic case leaving N minus pessimistic-quantity to be sold after the peak. The other scenario is according to the optimistic forecast leaving Optimistic minus N of lost sales. The rule is trying to find the best N that would, overall, yield the least potential damage or loss-of-sales. Note that it is unrealistic to commit to perfect availability in short peaks.

The planning for the peak itself should include the exact placement of stock or resources at the start of the peak. In the case of selling hats at the Super Bowl event the different points of sale should get an initial amount, while the rest is stocked somewhere in the middle, making it possible to replenish, not from production, but from a central point, to the selling points. Similarly, in the case of policemen controlling the security during the game, there is a need to have policemen located at several critical locations, while others wait at a central point to help handling situations that are too severe for the stationed policeman to handle.

The focus of managing the after-the-peak period is to return to normal as fast as possible. This might include logistics, dumping large inventories and carrying reduced activity for some time.

Shifting demand from the peak to the pre-peak or after-peak, when applicable, is an important part of planning for short peaks. It exploits much better the constraint-at-the-peak and reduces the risk during the peak.

Short unanticipated peaks

Some organizations are aware of possible sudden emergence of a peak. For some, like the Fire Squad or the Emergency Room in a hospital, this is a critical part of their goal. So, certain stock, and/or capacity, are prepared for such a case, even though the actual timing of the peak is not known. Such organizations have a structured process for such a peak. Using the first three steps of the five-focusing-steps should be the core of the “book” on how to handle a big, but short, unanticipated peak.

Organizations that are not prepared for such an occurrence have to improvise. Again, understanding the first three focusing steps is a major guidance in treating such a surprising peak.

Long unanticipated peaks

Unanticipated long peaks are pretty rare. When the demand starts to grow in an unexpected way, the challenge is to understand whether it is a trend or a peak, meaning the demand will go back to “normal behaviour”. One case is when the organization launches a big surprising hit without being aware of the potential success. Diagnosing whether this surprising success would continue or not is critical. If the organization wrongly assumes that the future success is guaranteed, meaning assuming it is a trend, and rushes to invest in doubling and tripling the capacity, the result could be catastrophic. The other obvious mistake is sticking to the current capacity levels and letting other competitors take over the new market demand. TOC has the tools to inquire the true causes behind the surprising surge of demand.

A basic TOC message when going into a surprising peak is to identify the emerging internal constraint and make quick changes to the procedures to match the new exploitation and subordination requirements. Of course, management needs good TOC knowledge to be able to adjust to the new situation in the best way. The remaining big challenge is whether to elevate the constraint, probably also other resources, or wait and see and maybe lose part of the future market demand.

As already mentioned, dealing with long anticipated peak of demand, has been treated in the post entitled: Facing Seasonality – the true problematic issue, see https://elischragenheim.com/2016/03/28/facing-seasonality-the-true-problematic-issue/

Very critical issue during festival and other seasons like winter and summer periods. Will go a long way to ensure no stock-outs at minimum inventory.

LikeLike