Improving the supply chain applies to two different scopes:

- Improving the performance of our own organization by improving the flow to our clients as well as the flow of supply from our suppliers.

- Improving the overall performance of a whole supply chain, across many different organizations, up to the end users of the end product/service.

My assumption is that the first, relatively local perspective of the supply chain, is the current common focus for considerable improvements. It already contains some thinking and vision on how that improvement is going to impact the overall supply-chain, especially as it looks on both suppliers and clients of the organization.

The long-term vision for the whole supply chain, developed by Eli Goldratt, deserves a special post sometime soon. Let’s focus now on the challenge of one link in the supply chain to improve its business. An organization usually has variety of products for variety of clients. It has also to maintain good relationships with various suppliers. Part of the value generated by the organization depends on the perceived value of the products, their quality, and the level of usage by the clients. A major point is the size of the target market segment that truly likes the end products. Another critical part of the value is the quality of the delivery to the clients. This fully depends on the management of the flow.

What blocks the flow of products according to the true wish of the market?

One of the two key obstacles to fast flow is batching, meaning the grouping of many pieces and working on them together as they move from one work station to the next. Naturally every batch serves many customers. Batching is in the center of attack by Lean, once called Just-in-Time, in order to come closer as possible to the idea of one-piece flow.

Batching is caused by either long setups or by certain resources that work on a whole batch, like ovens or transportation vehicles. One of means of Lean to dramatically reduce the batching is by reducing the setup time. Another mean is using more resources with lower capacity, for instance, smaller trucks for more frequent deliveries. The common concern is that these means would add cost.

A different key obstacle of the flow is lack of enough capacity, which causes long wait time. The first obstacle, batching, clearly impacts the second, the lack of capacity. When the batches are smaller capacity is spent on more setups, which seems like cost is wasted. TOC clearly shows this is not necessarily the case. But, it is certainly possible that too many setups would turn the specific non-constraint resource into a bottleneck, causing huge delays.

TOC has the right tools to deal with the obstacles, and by that maintain good flow, without becoming too orthodox, through sensible management of capacity and considering the real impact on cost and on the demand.

The two obstacles seem to be a major problem because of their impact on the flow of products and services and through that on the organization goal. But, when we examine the goal there is even more critical obstacle that makes the life of all managers so difficult:

Having to deal with the considerable uncertainty of the demand

The connection with managing the flow is soon to be analyzed. Meanwhile let’s understand the way common management practices deal with the uncertainty.

The common way most businesses deal with uncertainty is using forecasts to predict the future. The problem with forecasts is that they are, at best, partial information. In Probability Theory every stochastic behavior has to be expressed, at the very least, by two parameters. The most common are the predicted ‘average’ and the standard deviation. Forecasting methods use past results plus previous forecasts to generate the estimation of the average result and the ‘forecasting error’, which estimates the equivalent standard deviation for the coming forecast. The big problem of using the forecasts is that when looking for the demand in far away weeks the estimation of the ‘forecasting error’ becomes messy. Actually the whole notion of the forecasting error is problematic because when the error is relatively big, like when you look for the weekly forecast of one SKU at one location three months from now, then the burden on the decision maker is quite significant. Pretending the forecast determines accurately the demand seems like a good solution.

The personal fear of every decision maker of being proved wrong dominates the current practice. The usual response is that the forecast was RIGHT but the execution wrong – this provides a way to blame somebody else.

In reality the demand at any specific geographical location fluctuates in a much bigger way than the total inventory. Another complicating factor is that the level of uncertainty grows sharply with time. The longer the horizon the weekly/monthly demand forecasts are subject to more uncertainty. The weekly demand a year from now might even be irrelevant, due to new products and/or different economical situation.

The practical ramification for every supply chain is that the upstream nodes in the supply chain face much harder decisions on what to make and how much of each specific item. This is because the time between the relevant decisions of what to produce, and the actual sales of the end-products is relatively long, which means high level of uncertainty.

If reality would have been deterministic then the two obstacles of flow would not matter and optimized solution for capacity utilization, using the optimal batches could have been provided by good, but routine enough, software algorithm. This is, of course, not our reality.

One critical insight should be well understood:

Instead of improving the forecast, which might be either impossible or very minor, it is possible to improve the flow throughout the supply chain to quickly react and adjust to the actual demand!

Even with fast reaction to actual demand we have to make sure there is enough stock either on-hand or in the pipeline, to answer the immediate demand. It seems impossible to determine the exact stock, due to the volatile uncertainty, but we can come up with a good-enough estimation and adjust it based on the actual behavior.

Estimating the right amount of stock is a kind of FORECAST! But, we need to be clever in how we use the partial information to come up with a good-enough estimation of how much stock to hold in the system. In TOC the underlining assumption is that the demand for tomorrow is roughly the same as today, unless we get a signal that this might not be the case. So, we need to be clever in analyzing the signals that the current stock level might NOT be right. There is no viable way to determine a precise number, and being slightly “mistaken” would not matter if the fast reactive flow to actual demand is working properly.

These are the key core insights of TOC for managing a supply chain. The process needs to be much more detailed, but this is certainly beyond this post.

Still a troubling question is:

Is “good enough” truly enough for an organization that values optimization?

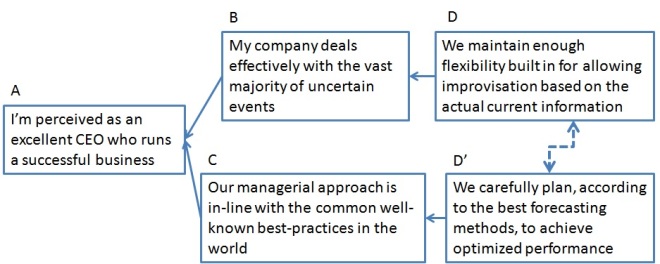

There is a strange conflict in the minds of most of the key managers in the area of supply chains. On one hand they recognize the need to improvise because everything changes all the time. Production managers are certainly used to improvisation. This requires having the appropriate infrastructure built in, like having enough stock and available capacity for sudden changes. On the other hand, managers are aware that improvisation means extra cost for the maintaining flexibility and such an approach cannot be optimized, and even worse, it is considered to be far from the common best practices of today. It is frightening to go against the common best practices, and every manager whose career depends on the judgment of others, like his boss or the board of directors, has a lot to fear from doing something different than what is accepted as “right”.

Here is the conflict cloud:

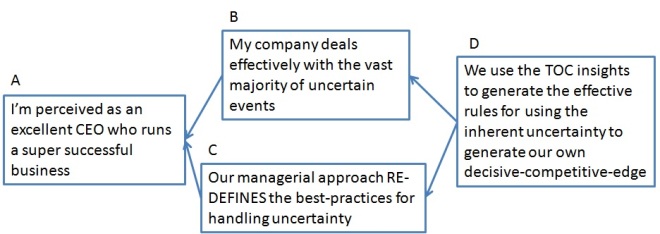

Actually, the TOC rules of dealing with uncertainty do not require frequent improvisations, but simply follow common-sense and make the decisions for relatively short periods of time, resulting from the fast flow that management is able to maintain.

What comes from handling uncertainty in such a way is being superior to most competitors in the eyes of the market, which could lead to very successful business.

The TOC approach challenges the need for the ‘C’ entity above to achieve the objective. So, the resolved conflict looks now like this:

Overcoming the natural fear to go against the common practices could be dealt with running a Proof-of-Concept. It has to be a good enough “proof”, and it has to limited, so even failing would not create too high perceived loss. A former post on Proof-of-Concept can be found at: https://elischragenheim.com/2017/02/26/looking-for-the-right-pilot-as-proof-of-concept/

One thought on “The Objective and the Challenge of Improving the Supply Chain – and the Personal Dilemma of the Key People”